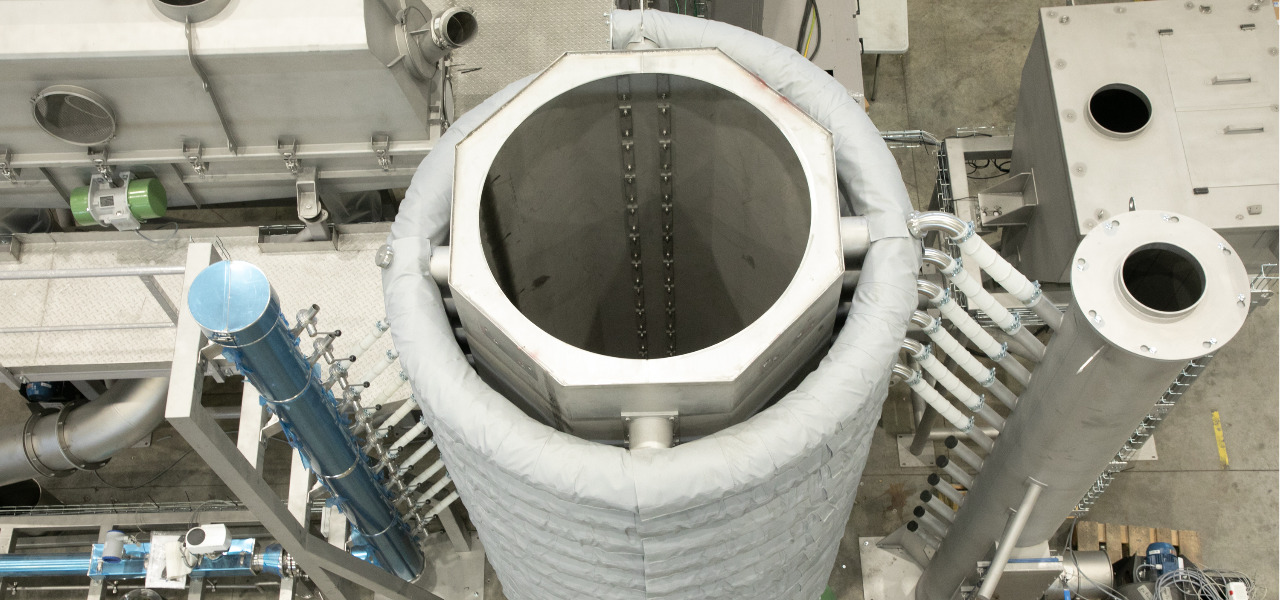

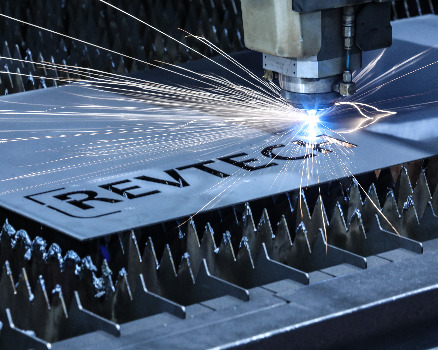

Fondée en 1997, Revtech bénéficie d’une expérience inégalée dans la création de solutions industrielles de traitement thermique et de pasteurisation d’ingrédients secs, de produits pulvérulents et gazeux.

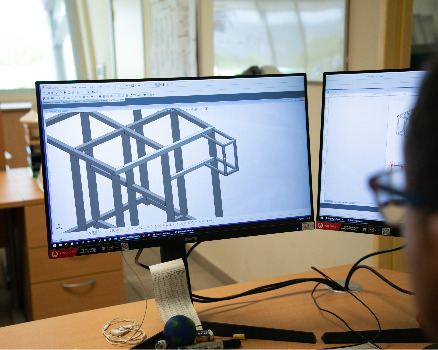

Reposant sur différentes innovations brevetées, Revtech propose à ses clients une démarche unique pour les accompagner dans la réalisation de leurs différents projets. Ainsi, de la conception à la fabrication, notre équipe d’experts met en œuvre toute une gamme de services individualisés pour vous garantir le retour maximal sur vos investissements technologiques.

Services et Solutions

Nos services

Bénéficiez de toute l’expertise de Revtech durant toutes les étapes d’étude et de réalisation de votre projet industriel.

Nos clients

Découvrez les différentes applications de la technologie Revtech et les multiples secteurs d’activité auxquels elles s’adressent.

Qui sommes-nous ?

Apprenez-en plus sur Revtech, son histoire, ses engagements et sa philosophie.

TÉMOIGNAGES CLIENTS

La technologie Revtech s’adresse à toutes les entreprises des industries agroalimentaire et chimique dont l’activité nécessite l’utilisation de procédés à des fins de débactérisation, pasteurisation, torréfaction, traitement thermique, séchage, pyrolyse… quelles que soient les familles de produits concernées (céréales, graines, fruits à coque, herbes, épices, biomasse, produits chimiques…).

Et puisque notre démarche est centrée sur la satisfaction de nos clients, nous sommes persuadés qu’ils sont les mieux à même de parler de nos prestations :