„Proximity Malt verkörpert drei Schlüsselprinzipien: lokal, nachhaltig und engagiert. Die Vision hinter diesem Projekt war es, in Zusammenarbeit mit lokalen Brauereien ein regionales Unternehmen zu gründen, das sich auf die lokale Getreideproduktion und eine nachhaltige Logistik stützt. Diese neue Generation von Mälzereien fügt sich perfekt in die (R)Evolution des Craft Brewing ein. Was die geografische Lage betrifft, so waren Colorado und Delaware, wo unsere beiden Mälzereien gebaut wurden, aufgrund der Produktion von gemälzter Gerste und der starken Präsenz von Handwerksbrauereien eine natürliche Wahl.

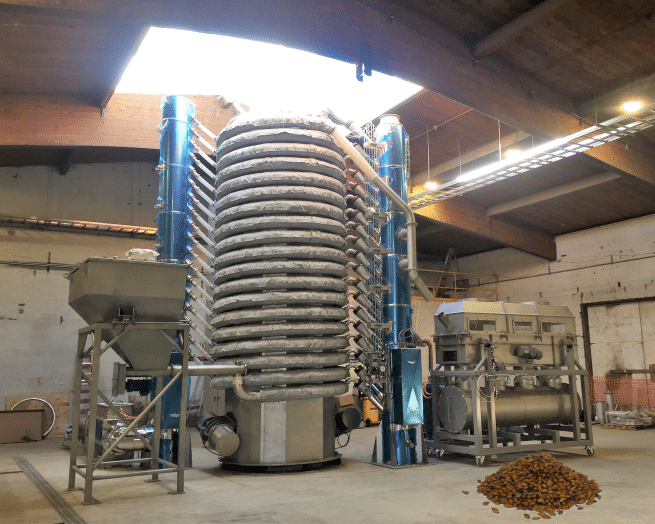

Um unsere Ziele zu erreichen, brauchten wir einen umweltfreundlichen, hochmodernen Röster: den REVTECH VERY UNIQUE ROASTER. Proximity Malt war das erste Unternehmen in Nordamerika, das diese Technologie einsetzte.

Was macht unseren Röster einzigartig? Als Mälzer müssen wir uns an sehr spezifische Richtlinien halten, bei denen jede Stufe des Röstprozesses entscheidend ist. Unsere Technologie steht vor Herausforderungen, die sowohl mit dem Produkt als auch mit der Umwelt zu tun haben, darunter:

Integrität des Korns: Das schonende Antriebssystem erhält die Integrität des Getreides im Vergleich zu traditionellen Röstern.

Präzision und Gleichmäßigkeit: Gleichbleibende Verarbeitungsbedingungen und eine präzise Kontrolle von Temperatur, Feuchtigkeit und Verweilzeit gewährleisten die Gleichmäßigkeit der Zielröstung.

Konsistenz der Charge: Die Wiederholbarkeit der präzisen Rezepte, die sanfte Bewegung und die gleichmäßig angewandte Hitze sorgen für eine gleichmäßige Röstung von Kern zu Kern.

Ressourceneffizienz: Die hohe Wärmeübertragung und das Fehlen von Verbrennungsgasen führen zu einem saubereren Prozess.

Vielseitigkeit: Die Technologie kann jedes Getreide rösten.

Sicherheit: Der minimale Sauerstoffgehalt garantiert die Verwendung von sicheren Röstgeräten.

Wir betreiben eine umfangreiche Forschung und Entwicklung, die der Schlüssel zu einem großen Portfolio an Spezialmalzen ist. Diese Mission stützt sich auf unsere Revtech-Pilotanlage in unserer Zentrale in Wisconsin. Unsere Büromitarbeiter können diese Experimente bestätigen, indem sie einfach die Röstgerüche in ihren Büros riechen – eine echte Teamleistung!

Die gesamte Palette an Farben und Geschmacksrichtungen, die unser Röster ermöglicht, erlaubt es uns, die Nachfrage jedes Craft-Brauers zu befriedigen, von Darrmalz bis Schwarzmalz, einschließlich Biskuitmalz, und es werden immer mehr.

Die Zufriedenheit unserer Kunden treibt unser erfahrenes Team von Mälzern dazu an, mehr Produktflexibilität und Kontrolle als je zuvor zu entwickeln. Wir danken dem Revtech-Team für seine Unterstützung, einschließlich der Fernhilfe, und für unsere Zusammenarbeit!“