Revtech’s technology embarks on a 6,000 miles journey to Thailand, but nobody had to push the machine over that distance.

Sonia Fuchez, Célia Schlosser

LET’S ZOOM IN ON THE PILOT UNIT TECHNOLOGY, AS EXPLAINED BY MARTIN MITZKAT, ENGINEER, AND FOUNDER OF REVTECH

Our small pilot machine can mimic a larger Revtech system by recirculating the product. Instead of the product exiting at the top in one pass, it continuously circulates within the machine. This means the product travels through the system multiple times, not just once. With only four spirals, the residence time would be too short, so the entry point is connected to the exit to ensure continuous recirculation.

As an example, if you need a 30-minute residence time in a big Revtech, then you will need 10 cycles of 3 minutes with the pilot unit! Then you empty the machine, check the quality of the product, and you can extrapolate the results.

These machines have been used by several private companies that already own a Revtech but want to develop and test new recipes for their products.

At the moment, we have two other pilot machines in the south of France. One is equipped with 4-inch tubes, and the other is equipped with 8-inch tubes. The latter is for very high flow. Our pilot units are ready to be shipped globally, allowing us to expand our international footprint and bring our innovative solutions to markets around the world. So, if you need our pilot unit for pasteurization or steam sterilization of herbs, spices, grains or seeds, do not hesitate to reach out.

REVTECH BREAKS NEW TECHNOLOGICAL GROUND IN THAILAND WITH THE INSTALLATION OF A PILOT MACHINE AT THE EECI.

Revtech Process Systems, headquartered in Loriol-sur-Drôme, France, is at the forefront of thermal processing technology. We specialize in creating and producing equipment for a range of industries, such as food, pharmaceuticals, and chemicals. Our mission is to improve industrial processes by making them more efficient, safe, and sustainable.

Let’s meet with experts from Revtech Process Systems to discuss this project in Asia, but first, a brief presentation of our partner in this adventure.

THE EASTERN ECONOMIC CORRIDOR OF INNOVATION

Located in Wangchan District, Rayong Province, the EECI is a symbol of the innovation that Thailand aims to provide to its people. Their goal is not only to link innovation and investments to their industries but also to foster a collaborative environment for technological advancements.

The innovation ecosystem offered by EECi benefits both private and public entities by allowing them to establish their research and innovation operations on-site and validate their innovations before mass commercialization.

At EECi, you can find facilities such as pilot plants, plant factories, smart greenhouses, demonstration plants, and testbeds. This aligns perfectly with Revtech’s mission to enhance efficiency, safety, and sustainability in industrial processes. Therefore, the EECI provides an ideal framework to test our technology in a new and stimulating environment.

The values, commitment, and vision of EECi, along with its strategic geographical location and the fruitful exchanges we’ve had with them, have solidified our decision to pursue this high-potential collaboration. This partnership represents a true win-win situation. The solution originated from a collaborator in Thailand who suggested, instead of using it for just one potential client, why not leverage it for several? This innovative approach led us to EECi, where we can maximize the impact of our efforts.

THE PROJECT

Now, let’s discuss with our sales engineer on how he found a place for the pilot at the EECI.

We contacted them, and a startup company hosted by the EECI offered to share a hall with other food and cosmetics machines, and that’s how the collaboration started. Now, here we are, for 6 months, maybe more. It is a really good opportunity for us to share that hall; our pilot unit is exposed to real potential for development, not only in one country but also in a whole part of the world.

How do Revtech and Thailand meet in terms of objectives then?

The proposition for trials is open to international companies. In Thailand the administrative procedures are straightforward, as evidence by the ease of obtaining a visa, which surely makes things easier for our partners and future partners in terms of administrative work.

Thailand really wants to develop its economic potential, which is why they make travel from foreign countries easier, and it is also simpler to make samples travel: you can get any product from any part of the world without any real difficulties. Thailand has a significant influence across Asia due to its strategic location, and entering the country for business purposes is made easy for our prospects. The EECI is conveniently located just 1.30 hours from Bangkok airport, ensuring easy access for pilots and visitors. The region boasts excellent connectivity with direct flights to numerous major Asian cities, facilitating seamless travel.

The EECI is renowned for its robust manufacturing and industrial base, supported by business-friendly policies that foster growth and innovation. Companies operating here benefit from cost-effective operations, making it an attractive destination for businesses looking to expand in Asia.

This pilot is going to allow us to reach a market that is fully developing at the minute…

Indeed, we hope that these tests will allow us to share the efficacy of our technology with new partners! This is an important milestone for Revtech in terms of collaboration with Asian countries.

But, did you encounter any difficulties with the process? What about conditions, calculations, or technical aspects…

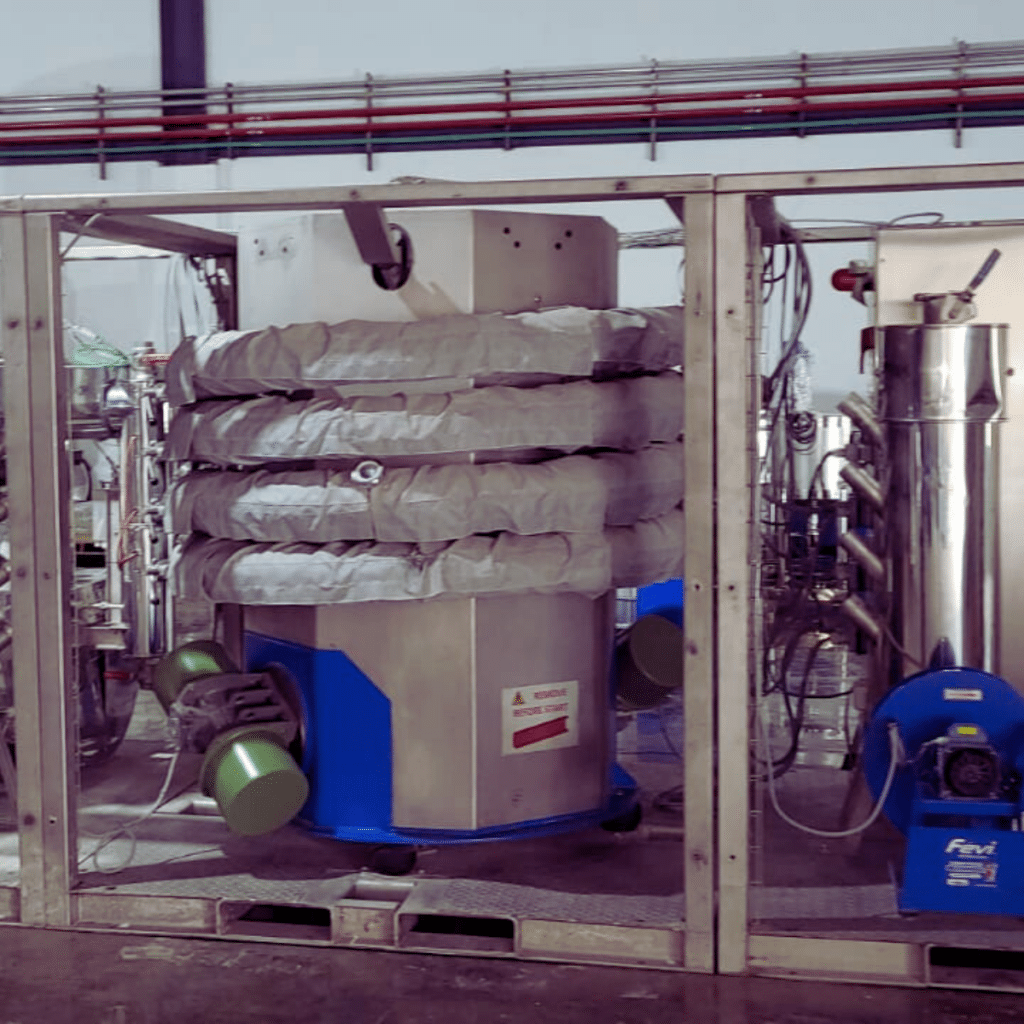

Well, we didn’t encounter any real difficulties. The hall is really adapted and welcoming for a small industrial pilot machine. The pilot unit is housed in a container, making it extremely compact and designed for cost and time-effective installation. Its portability allows for easy relocation.

The hall was ready for us, and we simply had to “plug and play.” It was as straightforward as setting it up and connecting it to the utilities (electricity, water, etc.) and exhaust systems.

We started the tests the very next day, showcasing the remarkable speed and efficiency of our process. And what’s really important is that you don’t need massive quantities of products for the tests, you can achieve great results with just 30 kgs of spices or seeds.

What precisely can be done with this unit? You talk about small quantities and great results; can you give us more information?

Our system features a hopper that accommodates small quantities, allowing for precise control. We can also heat at various temperatures and for different residence times, indeed, our pilot unit is equipped with a small boiler for steam injection and for hot air injection, and we can also manage the exhaust efficiently. Just like with big Revtechs, you can perform roasting and torrefaction tests. They can also reach pyrolysis temperatures for biomass treatment.

And what can be achieved more precisely?

Well, this setup enables the treatment of a wide range of Asian products, different types of spices and herbs like coriander, garlic or cumin for instance, and also seeds such as sesame…actually, we can process dry ingredient ranging from flours to larger items like cinnamon sticks. We can perform a myriad of applications, including 5-log pasteurization, toasting, enzymatic stabilization, and modification of functional properties.

You played a crucial role in the project. Thanks to your technical expertise and deep knowledge of Revtech, you initiated and supervised the entire project from Thailand, back to France also, but we can say that you really helped out on site with installation and start-up, ensuring the smooth running of the project at each stage. As a conclusion, what will you take away from this experience?

In conclusion, this pilot project in Thailand represents a significant milestone for Revtech, showcasing the capabilities of our technology in the Asian market. This collaboration not only opens doors to new partnerships but also strengthens our presence in a rapidly developing region. We are excited to see the results of this collaborative effort and look forward to further expanding our footprint in Asia, driving innovation and growth for years to come.

Meet the EECI: https://www.eeci.or.th/en/

Want to know more about our pilot unit?