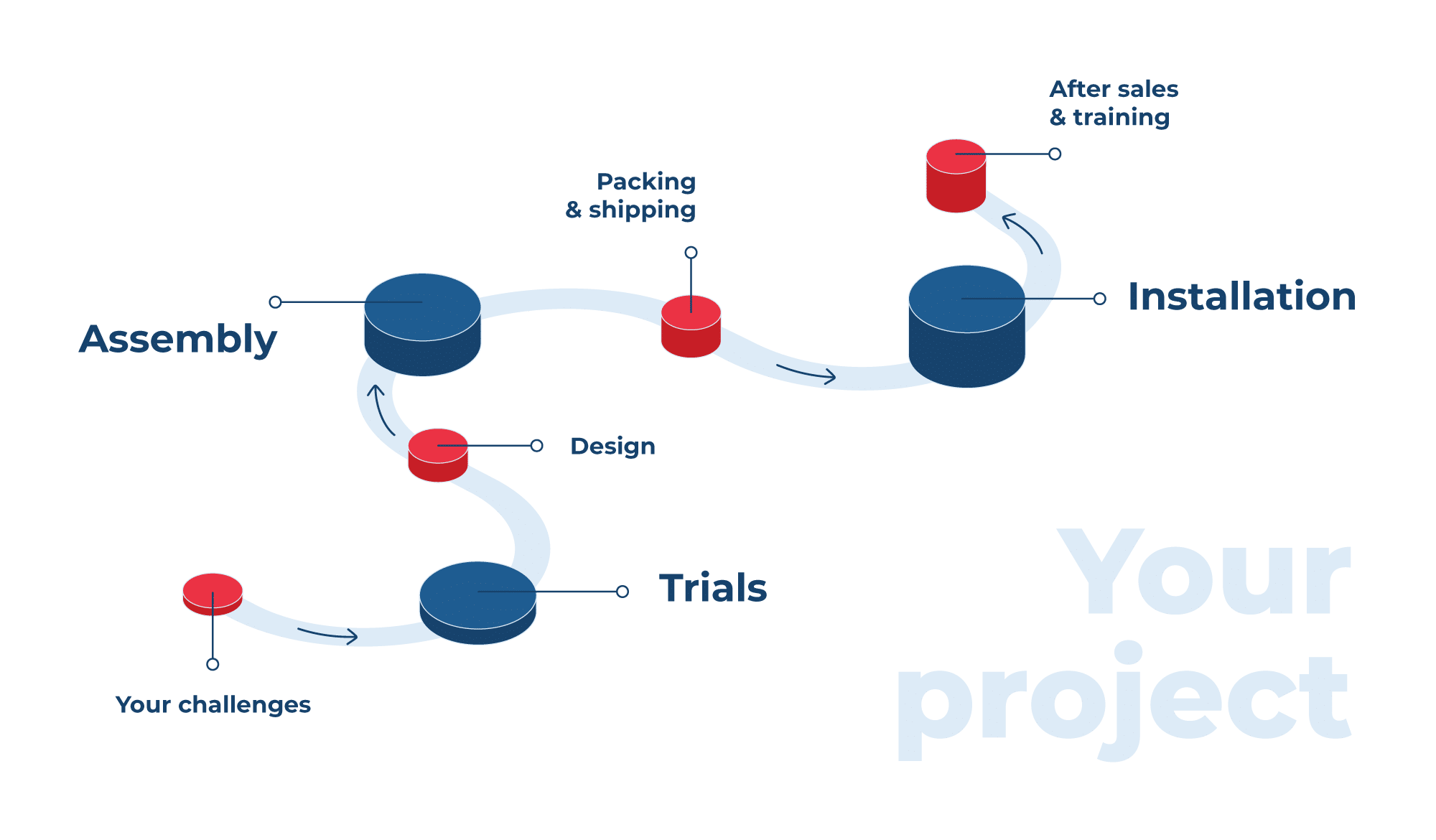

- Your challenges

We are committed to gaining a comprehensive understanding of your requirements, including the products you handle, your operational processes, required applications, and the challenges you encounter. The better we know you, the better we can design a solution answering your needs.

- Trials

With years of experience in conducting trials across a wide range of products and applications, we are well-equipped to offer you turnkey solutions. If you want to conduct trials on your products, our dedicated team of R&D technicians and process engineers is at your service, and two pilot units are at your disposal. These feasibility trials allow us to pinpoint optimal parameters such as temperature, residence time, flow rate, and gas injections. We meticulously collect samples for internal analysis or third-party evaluation, ensuring the highest standards of precision and reliability.

- Design

Once we determine the best solutions for your needs through our experience and feasibility trials, we proceed to develop your industrial solutions based on the defined specifications. Our team of industrial designers will create the complete unit using the latest 3D software, allowing for virtual verification of every part of the installation.

Each stage of the design is submitted for your approval, ensuring that your preferences and input are considered as early as possible in the design process.

- Assembly

After all components have been sourced from long terms suppliers and delivered, our highly trained and experienced technicians begin assembling the complete heat treatment unit in our custom-built workshop in France. The assembly team works closely with the design team, ensuring continuous communication to meet the exact design criteria. After assembly, the unit’s operation is validated using real products and conditions that closely mimic those of the future plant. Addressing any potential issues at this stage is crucial to ensure the unit meets your requirements and minimizes the time needed to reach production levels once installed on your site.

- Packing & shipment

Following various quality control steps, the unit is ready for shipping. With over 180 units installed worldwide, Revtech has extensive experience in shipping to nearly any destination. The unit is partially dismantled and carefully packed to ensure protection during transport.

- Installation

Meanwhile, our technicians and engineers are actively preparing for the machine’s arrival at your plant. They will supervise the installation, commissioning, and on-site start-up, as well as train your team.

- Aftersales & training

At Revtech, we understand the critical importance of reliable after-sales support. While our installations are designed for high reliability, we are committed to providing exceptional after-sales advice and assistance. Utilizing the latest communication technologies, we ensure that no matter where you are, we can promptly respond to your requests for information, updates, and service through the remote access capabilities of our control systems.

To help you get the most out of your Revtech system, we have developed comprehensive training programs. These programs are designed to enhance your skills and knowledge, ensuring you are fully equipped to manage and optimize your Revtech settings.

Testimonials