New battery recycling technology

Lithium-ion technology-based batteries (LIB) are commonly used in electric vehicles due to their energy efficiency and durability. However, their recycling is a major challenge due to the complexity of their design. Additionally, batteries are composed of multiple layers of nested materials with different chemical properties, making their disassembly and sorting complex.

Furthermore, the absence of international regulations governing battery processing further complicates recycling on a global scale. Despite these challenges, the recycling of LIB is essential to reduce electronic waste and recover the valuable metals they contain. Many initiatives are being implemented to encourage the industry to recycle used batteries, several companies are working on developing more efficient and safer recycling solutions. Indeed, lithium-ion batteries present a potential of explosion and fire hazards during their pre-sorting and grinding due to the organic compounds (electrolytes) they contain, making them difficult to handle.

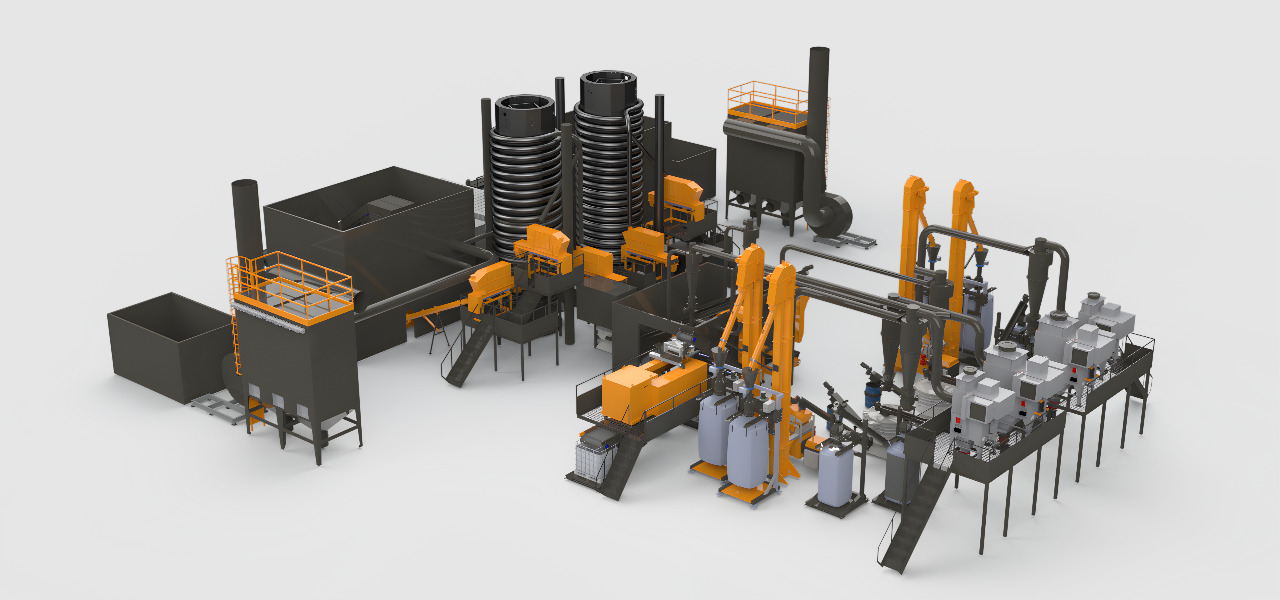

The EVAPOR8 project is funded by the French environmental agency (ADEME), in which the companies Revtech, MTB Manufacturing, and the LEPMI laboratory have combined their skills to develop a continuous process for shredding and deactivating LIB. The process consists of continuously shredding the batteries in an inert atmosphere using MTB technology, then heating the shredded materials at atmospheric pressure in the Revtech's vibrating and heating helical spirals to achieve thermal desorption, recovery, and valorization of electrolytes, without altering other solid fractions. The crushed material, free of any flammable compounds, is recovered at the end of the process and then sorted to recover the various solid constituents, including the blackmass. We have been able to demonstrate that the blackmass obtained can be reused to manufacture new Li-ion batteries or for other industrial applications. This process is safer, more efficient, more economical, and more environmentally friendly than existing recycling methods.

In conclusion, this project removes the final obstacle to the environmental relevance of electrifying transport, which is set to experience major growth in the coming years, and to contribute to France's independence from precious metals. The EVAPOR8 project directly contributes to this objective by developing an innovative, efficient, and safe industrial process that can recover almost all materials present in Li-ion batteries.